How to Choose Ultrasound Machine Manufacturers

Selecting an ultrasound machine manufacturer isn’t just a purchase decision—it’s an investment in clinical accuracy, operational efficiency, and long-term patient care. With options ranging from global giants to regional specialists, the process can feel overwhelming. But by focusing on key priorities and verifying critical credentials, you can find a partner that aligns with your practice’s needs.

Below is a actionable framework to guide your choice—plus why one manufacturer stands out from the crowd.

Best Guide for Global Buyers to Choose Ultrasound Machine Manufacturers

1. Map the Supplier Landscape First

Start by understanding the three main tiers of ultrasound suppliers to narrow your search:

International Giants: Brands like GE or Samsung offer mature technology and global reach but often come with premium pricing.Mid-Size Specialists: These firms balance innovation and flexibility, focusing on specific clinical niches (e.g., OB/GYN, point-of-care).

Regional Suppliers: Ideal for local needs but may lack advanced R&D or spare parts availability.

For any tier, prioritizereliability (track record of machine uptime),service history (how quickly they resolve issues), andspare parts access—delays here can disrupt clinics for weeks. A 2025 hospital study found that ultrasound downtime cuts imaging department revenue and creates patient backlogs, making these factors non-negotiable .

2. Prioritize Warranty and Post-Sales Support

The true cost of an ultrasound machine isn’t just the sticker price—it’s the hidden expenses of repairs and downtime. Look for:

Extended Warranties: Beyond the standard 12 months, especially for high-wear parts like probes.Preventive Maintenance (PM): Proactive servicing reduces downtime by up to 40%, according to failure mode analysis research .

Training Programs: Both basic operator training and advanced elective courses ensure your team maximizes the machine’s capabilities.

Avoid manufacturers that treat support as an afterthought—delayed repairs or untrained technicians can undermine your investment.

3. Drill Into Service Contract Details

A vague service contract is a red flag. Ask:

What’s Covered? Does it include probe repair, multi-modal equipment support, or mobile service for field clinics?Response Times: Will they send a certified technician within 48 hours for urgent issues?

Cost Transparency: Are there hidden fees for emergency service or replacement parts?

Fixed-price, all-inclusive contracts are best—they eliminate budget surprises and help you plan for long-term ownership .

4. Match Specifications to Your Clinical Niche

Ultrasound needs vary wildly by specialty:

OB/GYN: Requires high-resolution imaging for fetal monitoring.General Imaging: Needs versatility for abdominal, cardiac, or vascular exams.

Point-of-Care: Demands portability and quick startup for emergency settings.

Don’t settle for a “one-size-fits-all” machine. Look for manufacturers that offercustomization—whether adjusting software tools or adding specialty probes—to fit your workflow.

5. Verify Credentials and Capabilities

Reputable manufacturers back their products with third-party validation:

Certifications: ISO9001 (quality management), CE (European compliance), and FDA (U.S. approval) are minimum requirements.

Production and R&D: Do they have in-house facilities or outsource key steps? A full industry chain (from mold-making to assembly) ensures quality control at every stage .

Skip brands that can’t prove their technical or quality credentials—your patients deserve reliable equipment.

6. Compare Pricing and Financing

Balance budget with value:

New vs. Refurbished: New systems offer longer lifecycles (5–7 years), while quality refurbished models work for budget-constrained practices (just ensure they include a warranty).Financing Options: Loans with 84-month terms or equipment leasing can reduce upfront costs, even covering installation and support .

Remember: The cheapest option often costs more in the long run if it lacks support or durability.

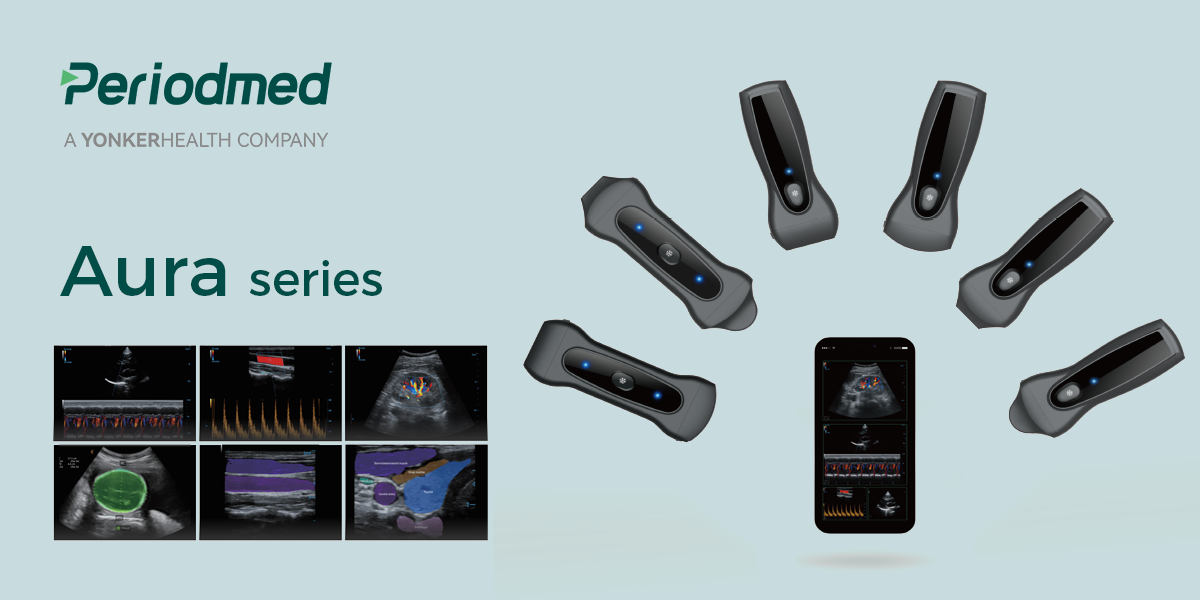

Why Periodmed Is Your Top Choice

Periodmed emerges as a standout partner for practices of all sizes. Here’s why:

Unmatched Manufacturing and R&D

Periodmed’s 30,000㎡ intelligent manufacturing base in China integrates every step of production—mold design, injection molding (4,000㎡ workshops), SMT (90% automation rate), and assembly . Dual R&D centers in Shenzhen (a tech hub) and Xuzhou (a manufacturing hub) drive innovation while ensuring practicality. For customization, they offer both large-scale lean production lines and dozens of flexible assembly lines to meet niche needs.

Global Quality Assurance

Periodmed holds ISO9001, CE, FDA, and CFS certifications—proving compliance with the world’s strictest medical device standards. This means their machines meet the same benchmarks as international giants, but without the premium price tag.

Customer Support

From warranties to on-site technician visits, Periodmed’s support aligns with clinical priorities. Their training programs ensure your team masters specialty features, while transparent service contracts eliminate hidden costs.

Wrapping Up

Choosing an ultrasound manufacturer requires balancing technology, support, and value. By mapping the landscape, verifying credentials, and prioritizing long-term support, you can find a partner that enhances your practice’s capabilities.

Periodmed checks every box: a full industry chain for quality, global certifications for reliability, and flexible solutions for every clinical need. Whether you’re a large hospital or a small clinic, their combination of innovation and service makes them the smart choice.

Ready to learn more? Contact Periodmed today [email protected] to discuss your ultrasound needs.

EN

EN CN

CN